Hi-Power II Belt

Gates Hi-Power II V-Belts

Example Part Numbers: A55, B100, C130, D152, E250

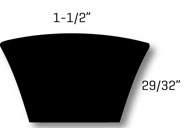

The letter at the beginning (A, B, C, D, or E) stands for the “section” or cross-section of the v-belt. The width of the belt increases from 1/2 (0.5) inches for an A-section belt to 1 1/2 (1.5) inches for an E-section belt. See the table below for the top width and thickness for each section. These cross-sections, are an industry standard, so Gates Hi-Power II belts can be used in place of other manufacturers’ belts of the same cross-section.

The numbers following the letter indicate the inside circumference (IC) of the belt. The outside circumference (OC) is found by adding an offset to the inside circumference. The offset is listed in the table below.

| Section | Top Width (in) | Nominal Thickness (in) | Offset (OC-IC) (in) | Example | Outside Circumference (in) |

|---|---|---|---|---|---|

| A | 1/2 (0.500) | 5/16 (0.312) | 2” | A55 | 57” |

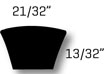

| B | 21/32 (0.656) also known as 5/8 | 13/32 (0.406) | 3” (1” above 210” IC) | B100 | 103” (100+3) |

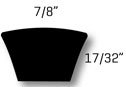

| C | 7/8 (0.875) | 17/32 (0.531) | 4” (2” above 210” IC) | C130 | 134” (130+4) |

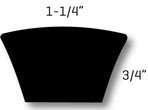

| D | 1 1/4 (1.25) | 3/4 (0.75) | 5” (3” above 210” IC) | D152 | 157” (152+5) |

| E | 1 1/2 (1.50) | 29/32 (0.906) | 7” (4” above 210” IC) | E250 | 254” (250+4) |

Design:

- Flex-Weave Cover – The Gates Hi-Power II vbelts are a line of wrapped belts that feature a patented single layer fabric construction for longer cover life. The cover protects the belt core from oil dirt and heat. The wrapped cover also makes the belt suitable for clutching applications.

- Flex-Bonded Cords – The Hi-Power II belt line utilizes a proprietary core material blend that strongly bonds the polyester cords to the body of the belt, resulting in uniform load distribution and absorption of bending stress without cord deterioration.

- Gates Curves – The belt cross-section has been optimized to provide proper cord support and full contact with the pulley to provide uniform loading, uniform wear, and increased belt life.

Recommended Applications:

Matching / Multi-Belt Drives:

Part of the V80 Matching System - Gates Hi-Power II v-belts can be used individually in a single vbelt drive or can be used in sets of 2 or more belts for higher horsepower applications. All belts in a multiple belt drive must be within a certain length tolerance in order for the belts to work together to provide the full design horsepower. In the past, manufacturing tolerances were wider and each belt was assigned a match number that indicated its exact length within the manufacturing tolerance. Gates invested heavily to reduce manufacturing tolerances. The result was the V80 matching system that ensures that every belt can be used in a matched set, regardless of batch or lot. An alternative to using a set of individual belts is to use a joined or banded belt such as the Gates A-Section Hi-Power II PowerBand belt.

Requirements Met:

RMA static conductivity requirements.

| Product Line | Features |

|---|---|

| Gates Hi-Power II |

-Heavy duty v-belt for multi-horsepower applications. |

| Gates Truflex |

-Light duty v-belt for fractional horsepower (FHP)

applications. |

| Gates PoweRated |

-Light duty v-belt for fractional horsepower (FHP)

applications and lawn and garden applications. |

| Gates Tri-Power |

-Heavy duty v-belt for multi-horsepower applications |

| Gates Predator |

-Extra-heavy duty v-belt for aggressive applications |